Schmidt Offset Coupling

Designed and described by Paul Dale

DESCRIPTION & INSTRUCTIONS

Designed and described by Paul Dale

This model is of a freelance design based on an illustration of such a coupling found on the Internet. The special features of the Schmidt offset coupling are that:

Both characteristics of the Schmidt Coupling are demonstrated in this model. The coupling as described here is capable of running at a considerable speed and it can transfer a surprising amount of power.

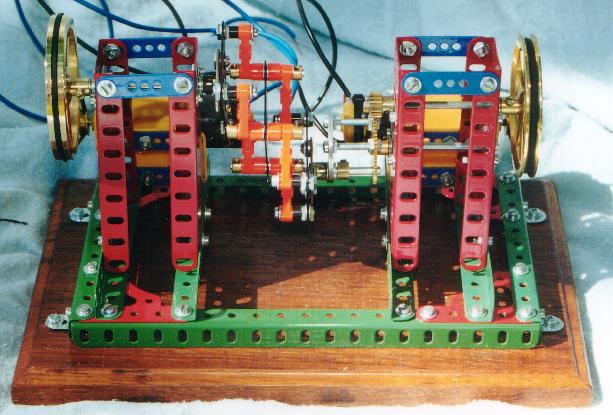

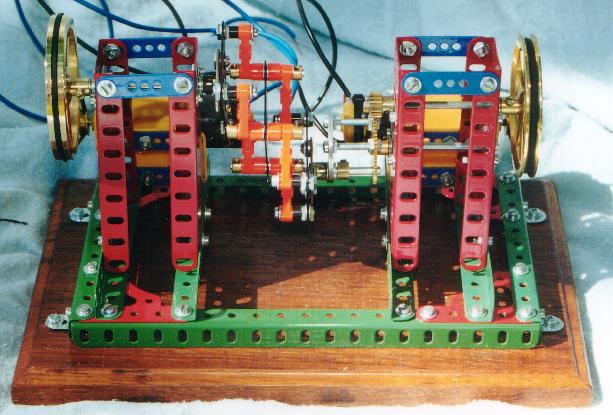

The rectangular base is constructed from two 9 1/2" angle girders and two 5 1/2" angle girders. Slotted flanges are all on the outside and facing downwards. All corners are braced using corner gussets with their long arms above and along the longer angle girders and their short arms below the 5 1/2" girders. Four more 5 1/2" angle girders are bolted to the long girders at holes 3, 6, 15 and 18 from the right. Their slotted flanges are arrange to be outside for each pair of girders. To the central holes of each of these four cross girders, bolt a flanged sector plate with their flanges facing each other pairwise. Strengthening and correct spacing is achieved by connecting the pairs of sector plates together using 2" strips, one each side at the tops and in the second and fourth holes from the bottom at the rear. These latter pairs of strips are used to provide mounting points for the two motors. All bearing holes on the sector plates have been reinforced by pairs of 1 1/2" narrow strips to reduce ware. These strips are not included in the parts list and can be left out without any loss of functionality.

The variable offset portion of the mechanism (on the right) is driven from a 19 tooth pinion on a 3 1/2" axle journalled in the third from top hole of the right hand pair of sector plates. This axle also has a pulley attached which is driven from the motor via a driving band. The pinion drives a 57 tooth gear on another 3 1/2" axle. This axle supports the variable offset cage which consists of two eight hole wheel discs bolted to the 57 tooth gear using three 1 1/8" bolts occupying three holes at right angles around the gear. The remaining hole in the square pattern holds a 1 1/2" axle which represents the output of the offset coupling.

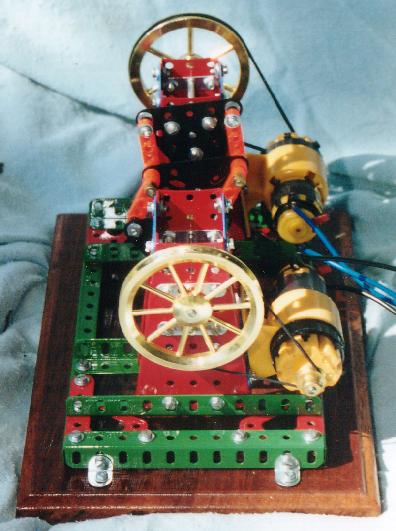

The input to the offset coupling is via a 3 1/2" axle which holds another pulley taking a drive, via bands, from its motor. The other end of the input axle is attached directly to the coupling mechanism. The coupling itself is made from three 2 1/2" triangular flat plates. The outer two are each bolted to six hole bush wheels which are in turn affixed to the input (3 1/2") and output (1 1/2") shafts. Each corner of these plates holds a pivot bolt which goes through the plastic strip, a small spacer and which is finally lock nutted to the triangular plate. The unattached ends of the plastic strips are paired up and connected using a 1 1/2" axle. This axle holds a collar, a plastic strip, a large plastic spacer, the central triangular plate, another large plastic spacer, the second plastic strip and finally another collar. I used aeroplane collars here to increase the tolerances available, however, standard collars should be usable. For the same reason, I used dome headed bolts to attach the six hole bush wheels to the outer triangular plates (heads inward). Again, this is probably not essential.

The input to the offset coupling is via a 3 1/2" axle which holds another pulley taking a drive, via bands, from its motor. The other end of the input axle is attached directly to the coupling mechanism. The coupling itself is made from three 2 1/2" triangular flat plates. The outer two are each bolted to six hole bush wheels which are in turn affixed to the input (3 1/2") and output (1 1/2") shafts. Each corner of these plates holds a pivot bolt which goes through the plastic strip, a small spacer and which is finally lock nutted to the triangular plate. The unattached ends of the plastic strips are paired up and connected using a 1 1/2" axle. This axle holds a collar, a plastic strip, a large plastic spacer, the central triangular plate, another large plastic spacer, the second plastic strip and finally another collar. I used aeroplane collars here to increase the tolerances available, however, standard collars should be usable. For the same reason, I used dome headed bolts to attach the six hole bush wheels to the outer triangular plates (heads inward). Again, this is probably not essential.

Note: The model is still assembled so this must be considered approximate.

| Part | Quantity | Part | Quantity |

|---|---|---|---|

| 6 | 8 | 38a | 6 |

| 8a | 2 | 38b | 6 |

| 9 | 6 | 54 | 4 |

| 16 | 3 | 59 | 8 |

| 18a | 4 | 76 | 3 |

| 19b | 2 | 108 | 4 |

| 23a | 2 | 111d | 3 |

| 24a | 2 | 147f | 6 |

| 24b | 2 | 186b | 2 |

| 26 | 1 | 260c | 6 |

| 27a | 1 | PDU | 2 |

Nuts, bolts & washers as required.

These instructions and the accompanying pictures are copyright material, and all rights are reserved. They are made freely available to Meccano modellers on condition that they are not copied and distributed in any form for sale, whether or not the sale is for profit or merely 'at cost'. Nor may they be distributed in incomplete form. Printed copies may however be made freely for personal use.

![]() © 2003, Paul Dale (pauli@moreton.com.au)

© 2003, Paul Dale (pauli@moreton.com.au)

"The Meccano Model Library" website is owned and run by Chris Bourne (cfpb@lineone.net)

Website designed and maintained by Donna Smillie (dms@zetnet.co.uk)

http://www.users.zetnet.co.uk/dms/meccano/dale/schmidt/index.html